澳美铝业自2005年成立以来,通过精益生产,卓越经营,取得良好的商业口碑和业绩。2021年,是澳美铝业成立15周年,经历15载变迁,铝加工产品的应用更加多元,技术革新日新月异,澳美铝业紧随时代脉搏,无论在设备硬件更新,材料研发,产品应用领域以及可持续发展方面都取得突破进展。放眼未来,铝型材应用的新纪元即将来临,澳美铝业将通过15周年铝创新纪元专题,多维度介绍澳美产品的应用及优势,期待与各位共襄未来。

PMI has a good reputation and achievement though LEAN production and excellent operation since 2005. It's the 15th anniversary of PMI, PMI aluminum products have used in multiple fields with rapid update technologies in these 15 years. Following the pulse of times, PMI has made breakthrough progress in facility renewal, material development, product applications and sustainability development. A new era of aluminium extrusion applications is coming, we will create a special topic which called “A New Aluminium Era” to introduce our product applications and advantage. We are looking forward to walk with you in the future.

汽车保有量创新高,能源“减负”迫在眉睫

Car ownership has reached a record high, energy optimism is in rush.

汽车已经成为人们生活的必需品,据公安部统计,2020年我国汽车保有量为2.81亿辆,全年新增2424万辆.汽车市场的蓬勃发展带动了产业链的提升,最为突出的是一众新能源车企脱颖而出,成为市场瞩目的焦点。

Automobile has became the daily necessities in China where year 2020 car ownership has reached 281 million record by the Ministry of Public Security report. Fast development of automobile market has led to the upgrading of the industrial chain, particularly a group of new energy vehicle enterprises stood out and became the focus of market.

汽车保有量提升,也意味着更为巨量的能源消耗及污染物排放增加。2020年7月,我国正式实行《轻型汽车污染物排放限值及测量方法(中国第六阶段)》,就是国6标准,为减少污染物排放制定了行政举措。另外,国家也在大力发展新能源汽车产业,越来越多的新能源汽车品牌在市场上受到关注。

Energy consumption and pollutant emissions will increase as the car ownership fast growing. Emission limits and measurement methods (phase 6) has been officially implemented on July, 2020. It is an administrative measure in order to reduce the pollutant emissions. In the other hand, China is taking great efforts to develop new energy vehicle industry. More and more automobile brands of new energy have got attention in the market.

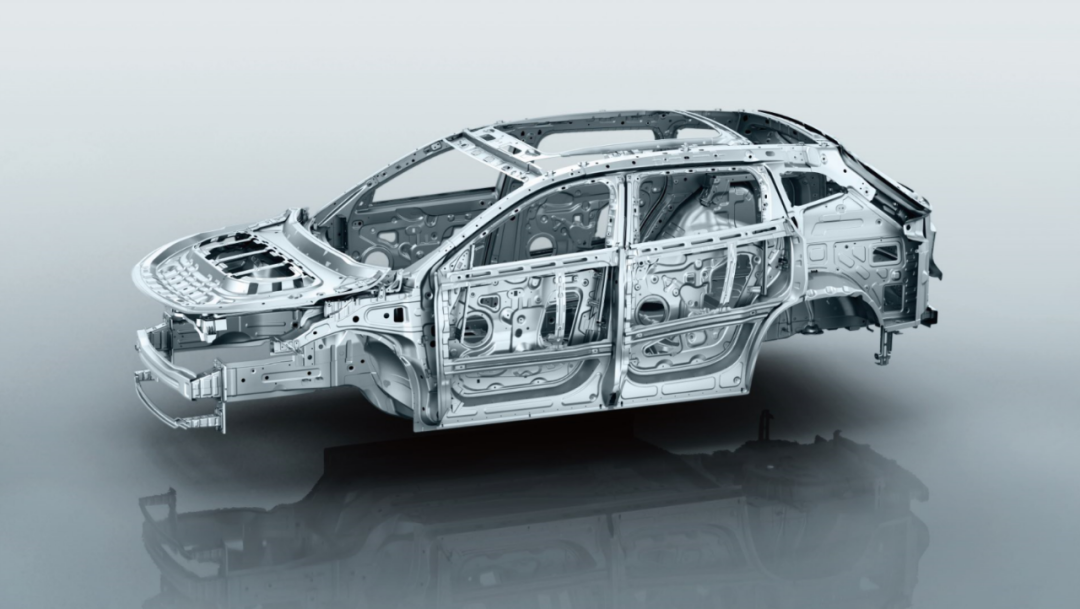

铝合金材料应用能持续提升汽车轻量化进程

Aluminium material applications will hasten lightweight progress of automobile.

要减低汽车运行的能源消耗,其中重点之一在于汽车轻量化达到提升能源使用效率。为达成以上目的,铝合金在汽车产业作为材料应用尤为流行。

以往汽车大量使用钢材作为车身及零部件结构材料,车身自重较大。铝的密度约为钢的三分之一,轻量化的效用非常明显。铝合金材料具备坚固且卓越的能量吸收性能,是应用最广泛的轻量化材料。近年来铝合金已经广泛应用于汽车防撞梁系统,天窗导轨,载客大巴车架,货车箱体等部位。随着新能源汽车产业发展,基于能源效率和散热需求,各个部件使用铝合金的比例更高,如汽车电池托盘等,电机外壳等,这方面为铝合金应用提供了极大的开发空间。

One of the key point for reduce energy consumption is to reduce the weight of car. It is trending to use aluminium as material for lightweight of automobile.

Steels always been used in car body and parts in the past & led to excessive car body weight. The effect is very obvious when use aluminium in automobile due to the density of aluminum is about one third that of steel. Aluminium is a high strength metal with excellent energy absorption performance & most widely used lightweight material. It is widely used for car collision beam system, car sunproof rail, bus frame, truck carriage etc. The new energy automobile industry is growing fast which trend car parts use aluminium, like battery trays and motor housing & large development space to be develop.

铝合金可循环利用的特性,能够减少资源浪费

The aluminium’s recycling feature enable in reducing resource wastage.

随着汽车更新换代频率加快,汽车报废数量也逐年增加。铝合金材料有可循环利用的优势,方便拆卸且能够100%回收利用,大大减少资源浪费,达到可持续发展的目标。

There is faster update frequency of automobile in these years will result the numbers of scrap cars increment year by year. Aluminium is easy to disassemble and 100% recyclable to reduce resource wasting and also help Sustainable Development.

澳美铝业携手整车及汽车零部件厂商,同创新纪元

PMI is working together with automobile manufacturers to build a new era.

澳美铝业生产的铝合金型材,广泛应用于国内外多家知名汽车品牌,为车企提供车身组件系统及零部件,得到各大车企的认同与信赖。同时,我们也与各汽车制造行业厂商合作,共同探讨汽车产业中的铝型材应用,共同开发全新的材料及产品,引领行业发展。

Aluminium extrusion products of PMI are widely used by world-wide well-known automobile brands. We supply car body system and parts to manufacturers & build trusts from them. In the meantime, we will cooperate with all manufacturers to lead the industry development by discuss about automobile industries’ leading aluminium application and develop all new materials and products.